How LiCON Uses Recycled Materials to Make AAC Blocks?

LiCON AAC Blocks are manufactured using sustainable, high-quality raw materials to ensure long-lasting durability and meet environmental responsibility.

-

Fly Ash

-

Cement

-

Lime

-

Sand

-

Water

Raw Materials Behind LiCON AAC Blocks

- Fly Ash (Industrial Waste Recycling) : Fly ash reused from thermal power plants minimizes waste and carbon impact, resulting in sustainable construction with eco-friendly benefits.

- Cement : Cement functions as a binding agent, improving the structural integrity, durability, and lifespan of AAC blocks, ensuring long-term building quality.

- Lime : It improves workability and stability, making building projects lighter, more aerated, easier to handle, and structurally reliable.

- Sand : It preserves uniformity and strength, enhancing the block's resistance to adverse weather conditions and supporting long-term performance.

- Water : It contributes significantly to the chemical process, generating a porous structure that improves insulation, durability, and overall block strength.

By using recycled fly ash, LiCON AAC Blocks support eco-friendly construction while maintaining superior quality and performance.

AAC Blocks for Stronger, Safer & Efficient Structures

Which is Better? LiCON AAC Blocks vs Traditional Clay Red Bricks

| Feature | LiCON AAC Blocks | Red Bricks (Clay Bricks) |

|---|---|---|

| Size | 600 x 200 x (100, 150, 200, 225) mm | 225 x 100 x 75 mm |

| Weight | Lightweight (9–19 kg/block based on size) | Heavier (17–40 kg equivalent volume) |

| Strength | Above 4 N/mm² (suitable for load-bearing) | 3–4 N/mm² (moderate strength) |

| Density | 550–650 kg/m³ | 1500–1700 kg/m³ |

| Water Absorption | 5–10% | 15–20% |

| Thermal Insulation | Excellent (0.16 w/mk, lowers energy usage) | Poor (0.81 w/mk, higher energy consumption) |

| Fire Resistance | Up to 6 hours | Up to 2 hours |

| Sound Insulation | 45 dB sound reduction | 30–40 dB |

| Seismic Resistance | High (absorbs shocks better in quake-prone zones) | Low (less resistant to seismic activity) |

| Workability | Easy to cut, shape, and install | Brittle and hard to modify |

| Mortar Joint Thickness | 3–5 mm with Joint mortar | 15–18 mm |

| Plaster Thickness | 10–12 mm | 15–20 mm |

| Speed of Construction | Faster (due to larger size & ease of handling) | Slower (more bricks and labor needed) |

| Eco-Friendliness | Sustainable (uses fly ash and eco-safe processes) | Not eco-friendly (depletes clay/natural resources) |

| Cost-Effectiveness | Lower material, labor & transport costs | Higher costs due to more materials & heavy weight |

| Structural Load | Reduces overall load on building | Increases dead load on structure |

Who Should Choose LiCON AAC Blocks for Building?

Method of Constructing AAC Block Walls & Precautions

Prepare a Flat & Dry Base

Ensure that AAC blocks are stacked on a flat and level surface. Use only completely dry blocks.

Clean the Block Surface

Brush off dust or rinse AAC blocks with water to remove debris before use.

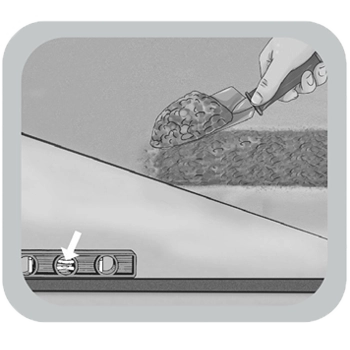

Lay the Base with Leveling

Use a sand-cement mix to create a level base and align the grooves of the blocks properly.

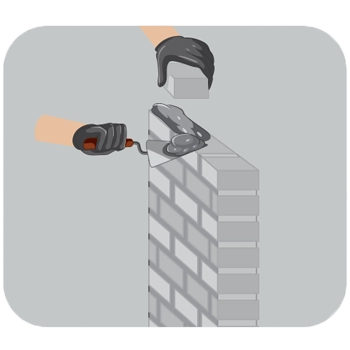

Apply Thin-Bed Mortar

Use a toothed trowel to spread 3–5 mm of Lycon mortar. If using conventional mortar, maintain 10–12 mm joint thickness.

Arrange Blocks in Straight Rows

Place AAC blocks in uniform rows on the prepared surface until the wall is completed.

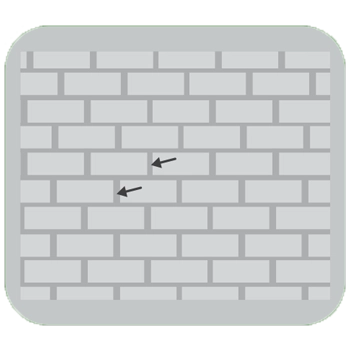

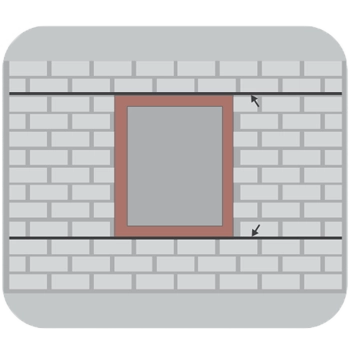

Stagger the Vertical Joints

Ensure vertical joints don’t align directly above each other; follow a staggered pattern.

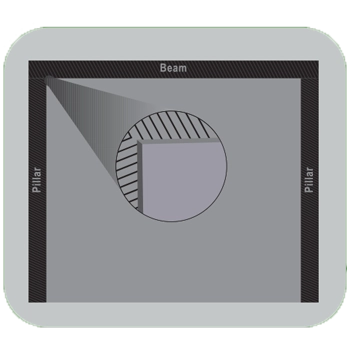

Add Coping Beams & Lintels

Install a coping beam every 4 rows and place a 6/8 mm lintel above windows.

Include Support Pillars

For longer walls, build a support pillar every 10 feet to improve structural stability.

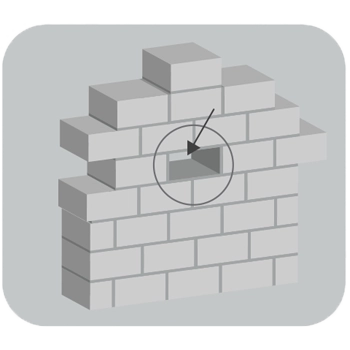

Provide Grooves for Electrical Work

Use power tools to make grooves in the blocks for wires and pipes.

Create a Groove After Plastering

After applying plaster, cut a 1 cm groove on top before the plaster sets.

Expereince

Choose LiCON AAC Blocks for faster, cost-effective construction with superior strength, thermal insulation, soundproofing, and eco-friendly benefits. Reduce project time, save on labor and material, and meet green building standards with confidence. Build smarter, stronger, and more efficiently with LiCON today!

Enquire NowFAQs About LiCON AAC Blocks for Every Construction Projects

- 4-inch block: ~ 9 kg

- 6-inch block: ~ 13 kg

- 8-inch block: ~ 16 kg

- 9-inch block: ~ 19 kg

Even at larger sizes, Licon AAC Blocks are significantly lighter than traditional clay bricks. This makes them easier to handle, faster to install, and more economical to transport, reducing labor effort and construction time.